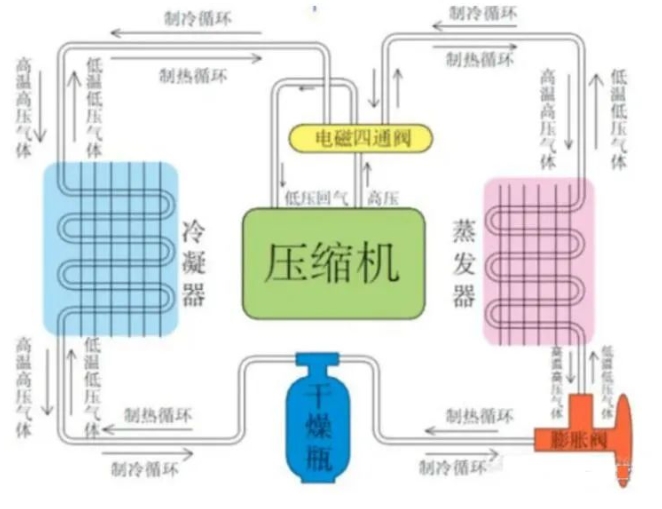

1. Umgomo wokulawula wesistimu ye-air-conditioning yemoto kagesi ehlanzekile ukuqoqa ulwazi engxenyeni ngayinye yemishini yokupholisa umoya ngokusebenzisa i-VCU (iyunithi yokulawula i-elekthronikhi), yakha isignali yokulawula, bese uyidlulisela kumlawuli we-air-conditioning (isifunda sokulawula) nge-CAN, ukuze isilawuli se-air-conditioning sikwazi ukulawula i-air-conditioning ye-air-conditioning yokulawula ukucindezelwa komshini wokukhipha umoyaair conditioning system.

Ukuxazulula izinkinga nezixazululo zezinhlelo zokupholisa umoya ezimotweni zikagesi ezimsulwa

Isistimu ye-air conditioning ayikwazi ukuqaliswa

Ngenkinga yokuthi i-air outlet ayiwuqhumisi umoya, ngokusekelwe ekuhlangenwe nakho okusebenzayo, kubhekwa ngokuyinhloko ukuthi imodi yokushintsha i-air conditioner ikumodi ye-defrost. Uma imodi ye-air conditioning ingeyona imodi ye-defrost, izisebenzi zokunakekela kudingeka zihlole isivinini esilawula isivinini kanye nentambo yamandla, ngokuvamile zisebenzisa i-multimeter ukuhlola i-voltage. Uma wonke amanani olayini engaphakathi kwesizathu, isifutha sidinga ukuhlolwa okwengeziwe nokushintshwa. Uma ukwehluleka kwesimo somoya kubangelwe umoya ophuma endaweni yokuphuma komoya kodwa kungekho moya obandayo ovunguzayo, udinga kuqala uhlole umthamo webhethri wemoto kagesi emsulwa ukuze uxilongwe futhi ulungiswe. Uma izinga lokushisa lenzwa lijwayelekile, udinga ukuhlola ipayipi kanye nokucindezela kwesiqandisi.

Umphumela wokupholisa wesistimu ye-air conditioning mubi

Indlela yokuxilonga yomphumela wokupholisa ongemuhle imi kanje: Ngesikhathi sokuhlolwa, qinisekisa ukuthi indawo ehlanzekile yemoto kagesi igcinwa phakathi kuka-20-35°C, setha ukuphuma komoya kwesiphephetha-moya ukuze kuqhume ngokugcwele, futhi izisebenzi zokunakekela zisetha isiphephetha-moya sibe yigiya eliphezulu kakhulu. Bese, xhuma ingcindezi ephezulu nephansi ye-air conditioner usebenzisa i-multifold pressure gauge bese ubheka ukufundwa kwegeji yokucindezela. Uma izinombolo ze-high and low pressure ziphansi kunokuvamile, lokho kubonisa ukuthi asikho isiqandisi esanele ku-air conditioning system. Uma inani liphansi kakhulu, libonisa ukuthi kukhona ukuvuza epayipini le-air conditioning futhi lidinga ukutholakala. Uma umfutho ophakeme ujwayelekile kodwa umfutho ophansi ungaphezulu kuka-0.3MPa, futhi izinga lokushisa lepayipi lomfutho ophansi liphansi kakhulu, kungase kubangelwe ukuhwamuka ngokweqile kwesiqandisi ngenxa yokulungiswa ngokweqile kwe-valve yokwandisa, ngakho ukulungisa i-valve yokwandisa kwanele.

I-air conditioning system inomsindo

Ngokudlidliza kwe-compressor nomsindo, kufanele siqale sinqume ukuthi kubangelwa ukwehluleka kwe-rubber shock absorber noma ukuxegiswa kwe-compressor fixing bolts. Uma i-rubber pad ingenaphutha ngemva kokuhlolwa, udinga ukuhlola ukuxhumeka kwamasekethe ahlukahlukene, njengokuxhumana kwesifunda sesigaba sesithathu phakathi kwe-compressor nesilawuli. Ngokwesibonelo, ninii-compressor yenza umsindo onzima wokungqubuzana, kungahlulelwa ngokuyisisekelo ukuthi i-compressor ngokwayo ilimele futhi i-compressor idinga ukushintshwa. Uma ifeni ejiyayo yenza umsindo omkhulu wokudlidliza, qala uhlole iphedi yerabha lapho kufakwe khona ifeni ejiyayo. Uma inkinga iqhubeka ngemva kokushintshwa, kungase kubangelwe ukuguga kwenjini yefeni elijiya futhi ifeni ejiyayo idinga ukushintshwa.

Ngaphezu kwamaphutha angenhla, isistimu ye-air conditioning nayo inezinkinga zokupholisa ngezikhathi ezithile. Kule nkinga, kubaluleke kakhulu ukuhlola ukuthi izinga lokushisa le-compressor lidlula inani elibekiwe lohlelo lonke lwemoto. Isibonelo, izimoto zikagesi ezimsulwa zibeka izinga lokushisa lokuvikela i-compressor libe ngu-85°C. Uma inani lidlula leli nani, isistimu izokhipha ngokuzenzakalelayoumyalo wokuvala i-compressor. Leli phutha ngokuyinhloko libangelwa ukwehluleka komsebenzi we-compressor refrigeration, okwenza izinga lokushisa le-compressor libe phezulu kakhulu, futhi isilawuli se-compressor sidinga ukushintshwa. Lapho ushintsha isilawuli, sebenzisa igrisi ye-silicone eshisayo ngokulinganayo endaweni yokuxhumana ukuze unciphise ukuvala kwe-compressor okubangelwa ukushisa ngokweqile.

Isikhathi sokuthumela: Apr-08-2024