Kusukela ngo-2014, imboni yezimoto zikagesi kancane kancane ishisa. Phakathi kwazo, ukuphathwa kwezimoto ezishisayo zezimoto zikagesi kuye kwashisa kancane kancane. Ngoba ububanzi bezimoto zikagesi azixhomekile kuphela kumthamo wamandla webhethri, kodwa futhi nobuchwepheshe besistimu yokulawula ukushisa kwemoto. Isistimu yokulawula ukushisa kwebhethri nayo inakhozizwelanced inqubo kusukela ekuqaleni, kusukela ekunganakeni kuya ekunakeni.

Ngakho namuhla, ake sikhulume mayelanaukuphathwa okushisayo kwezimoto zikagesi, baphetheni?

Ukufana nomehluko phakathi kokuphathwa kokushisa kwemoto kagesi kanye nokuphathwa kokushisa kwezimoto zendabuko

Leli phuzu libekwe endaweni yokuqala ngoba ngemuva kokuthi imboni yezimoto ingene enkathini entsha yamandla, ububanzi, izindlela zokuqalisa kanye nezingxenye zokuphatha ezishisayo zishintshe kakhulu.

Asikho isidingo sokusho okwengeziwe mayelana nezakhiwo zokuphatha ezishisayo zezimoto zikaphethiloli zendabuko lapha, futhi abafundi abangochwepheshe bakubeke kwacaca ukuthi ukuphatha okushisayo okujwayelekile kufaka phakathiair-conditioning uhlelo thermal ukuphathwa kanye nesistimu engaphansi yokuphatha okushisayo ye-powertrain.

Ukwakhiwa kokuphathwa okushisayo kwezimoto zikagesi kusekelwe ekwakhiweni kokuphathwa okushisayo kwezimoto zikaphethiloli, futhi kunezela uhlelo lokuphatha ukushisa okushisayo kwemoto kagesi kanye nesistimu yokulawula ukushisa kwebhethri, ngokungafani nezimoto zikaphethiloli, izimoto zikagesi zizwela kakhulu ekushintsheni kwezinga lokushisa, izinga lokushisa liyisici esibalulekile sokunquma ukuphepha kwayo, ukusebenza nokuphila, ukuphathwa okushisayo kuyindlela edingekayo yokugcina izinga lokushisa elifanele. Ngakho-ke, isistimu yokulawula ukushisa kwebhethri ibaluleke kakhulu, kanye nokuphathwa kokushisa kwebhethri (ukuchithwa kokushisa / ukuqhutshwa kokushisa / ukushisa ukushisa) kuhlobene ngokuqondile nokuphepha kwebhethri kanye nokuvumelana kwamandla ngemva kokusetshenziswa isikhathi eside.

Ngakho, ngokwemininingwane, kukhona ikakhulukazi umehluko olandelayo.

Imithombo yokushisa ehlukene ye-air conditioning

Uhlelo lwe-air conditioning lweloli likaphethiloli lwendabuko ikakhulukazi lwakhiwe i-compressor, i-condenser, i-valve yokwandisa, i-evaporator, ipayipi nokunye.izingxenye.

Lapho ukupholisa, i-refrigerant (ifriji) yenziwa yi-compressor, futhi ukushisa emotweni kukhishwa ukuze kuncishiswe izinga lokushisa, okuyisimiso sokuqandisa. Ngobaumsebenzi we-compressor idinga ukushayelwa injini, inqubo yesiqandisi izokwandisa umthwalo wenjini, futhi yilesi sizathu esenza sithi isimo somoya sasehlobo sibiza uwoyela owengeziwe.

Njengamanje, cishe konke ukushisisa kwemoto kaphethiloli ukusetshenziswa kokushisa okuvela esipholiseni esipholile senjini - inani elikhulu lokushisa okulahlwayo okukhiqizwa injini lingasetshenziswa ukufudumeza isimo somoya. Isipholile sigeleza kwisishintshi sokushisa (esaziwa nangokuthi ithange lamanzi) ohlelweni lomoya ofudumele, futhi umoya othuthwa isiphephethasi ushintshaniswa nokushisa kwenjini, futhi umoya uyashiswa bese uthunyelwa emotweni.

Nokho, endaweni ebandayo, injini idinga ukusebenza isikhathi eside ukuze inyuse izinga lokushisa lamanzi lifike ezingeni elifanele, futhi umsebenzisi kudingeka abekezelele amakhaza isikhathi eside emotweni.

Ukushisisa kwezimoto zamandla amasha ikakhulukazi kuncike kumahitha kagesi, izifudumezi zikagesi zinezifudumezi zomoya nezifudumezi zamanzi. Isimiso se-heater yomoya sifana nesomiso sezinwele, esishisa ngokuqondile umoya ojikelezayo ngeshidi lokushisa, ngaleyo ndlela unikeze umoya oshisayo emotweni. Inzuzo ye-heater yomoya ukuthi isikhathi sokushisa siyashesha, isilinganiso sokusebenza kahle kwamandla siphakeme kancane, futhi izinga lokushisa lokushisa liphezulu. Okubi ukuthi umoya oshisayo womile ikakhulukazi, okuletha umuzwa wokoma emzimbeni womuntu. Umgomo we-heater yamanzi ufana naleyo yesifudumezi samanzi sikagesi, esishisisa isibandisi ngeshidi lokushisisa, futhi isipholile esinezinga eliphezulu lokushisa sigeleza phakathi kwenkaba yomoya ofudumele bese sishisisa umoya ojikelezayo ukuze kuzuzwe ukushisa kwangaphakathi. Isikhathi sokushisa se-heater yamanzi side kancane kunesokushisa komoya, kodwa futhi sishesha kakhulu kunemoto yamafutha, futhi ipayipi lamanzi linokulahlekelwa ukushisa endaweni yokushisa ephansi, futhi ukusebenza kahle kwamandla kuyancipha kancane. I-Xiaopeng G3 isebenzisa isifudumezi samanzi esishiwo ngenhla.

Noma ngabe ukushisisa komoya noma ukushisisa amanzi, ezimotweni zikagesi, amabhethri kagesi ayadingeka ukuze kuhlinzekwe ugesi, futhi ugesi omningi usetshenziswaUkushisa kwe-air conditioning ezindaweni zokushisa eziphansi. Lokhu kubangela ukuncishiswa kwebanga lokushayela kwezimoto zikagesi ezindaweni ezisezingeni eliphansi lokushisa.

Qhathanisaed nge inkinga yokushisa okuhamba kancane kwejubane lezimoto zamafutha ezindaweni zokushisa eziphansi, ukusetshenziswa kokushisa kagesi kwezimoto zikagesi kunganciphisa kakhulu isikhathi sokushisa.

Ukuphathwa okushisayo kwamabhethri wamandla

Uma kuqhathaniswa nokuphathwa okushisayo kwenjini kwezimoto zikaphethiloli, izidingo zokulawula ukushisa kwesistimu yamandla emoto kagesi ziqine kakhulu.

Ngenxa yokuthi izinga lokushisa elisebenza kahle kakhulu lebhethri lincane kakhulu, izinga lokushisa lebhethri ngokuvamile lidingeka libe phakathi kuka-15 no-40.° C. Nokho, izinga lokushisa le-ambient elivame ukusetshenziswa yizimoto lingu -30~40° C, kanye nezimo zokushayela zabasebenzisi bangempela ziyinkimbinkimbi. Ukulawulwa kokulawula okushisayo kudinga ukuhlonza ngempumelelo nokunquma izimo zokushayela kwezimoto nesimo samabhethri, futhi kulawule izinga lokushisa elifanele, futhi kulwele ukuzuza ibhalansi phakathi kokusetshenziswa kwamandla, ukusebenza kwemoto, ukusebenza kwebhethri nokunethezeka.

Ukuze kuncishiswe ukukhathazeka kobubanzi, umthamo webhethri lemoto kagesi uya ngokuya uba mkhulu, futhi ukuminyana kwamandla kuya ngokuya kuya phezulu; Ngesikhathi esifanayo, kuyadingeka ukuxazulula ukungqubuzana kokulinda isikhathi eside sokushaja kubasebenzisi, futhi kwaba khona ukushaja okusheshayo nokushaja okusheshayo.

Mayelana nokuphathwa kwe-thermal, ukushaja okusheshayo okuphezulu kwamanje kuletha ukukhiqiza ukushisa okukhulu kanye nokusetshenziswa kwamandla okuphezulu kwebhethri. Uma izinga lokushisa lebhethri seliphezulu kakhulu ngesikhathi sokushajwa, lingase lingagcini nje ngokubangela ubungozi bokuphepha, kodwa liphinde liholele ezinkingeni ezifana nokuncipha kokusebenza kahle kwebhethri kanye nokusheshisa ukubola kwebhethri. Umklamo weuhlelo lokuphatha ukushisakuwuvivinyo olunzima.

Ukuphathwa kokushisa kwemoto kagesi

Ukulungiswa kokunethezeka kwekhabethe labahlali

Imvelo eshisayo yangaphakathi yemoto ithinta ngqo ukunethezeka komuntu ongaphakathi. Ukuhlanganisa nemodeli yezinzwa zomzimba womuntu, ukutadisha ukugeleza nokudlulisa ukushisa ku-cab kuyindlela ebalulekile yokuthuthukisa ukunethezeka kwemoto nokuthuthukisa ukusebenza kwemoto. Kusukela ekwakhiweni kwesakhiwo somzimba, kusukela ku-outlet ye-air conditioning, ingilazi yemoto ethintekile emisebeni yelanga kanye nomklamo wonke womzimba, kuhlanganiswe nesistimu ye-air conditioning, umthelela wokunethezeka komuntu ongaphakathi uyacatshangelwa.

Lapho ushayela imoto, abasebenzisi akufanele nje bazwe umuzwa wokushayela olethwa amandla anamandla emoto, kodwa futhi ukunethezeka kwendawo ye-cabin kuyingxenye ebalulekile.

Ibhethri lamandla okulawula ukulungisa izinga lokushisa

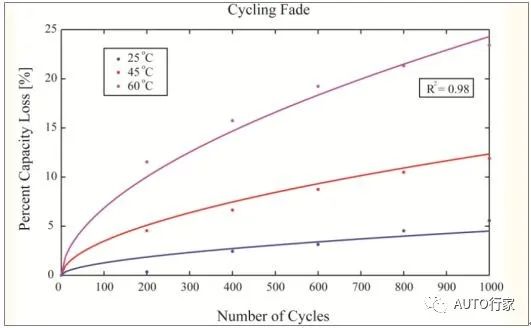

Ibhethri ekusetshenzisweni kwenqubo izohlangabezana nezinkinga eziningi, ikakhulukazi ekushiseni kwebhethri, ibhethri ye-lithium endaweni yokushisa ephansi kakhulu ukuncishiswa kwamandla kubi kakhulu, endaweni yokushisa ephezulu kuthambekele ezingozini zokuphepha, ukusetshenziswa kwamabhethri ezimeni ezimbi kakhulu kungenzeka kubangele ukulimala kwebhethri, ngaleyo ndlela kunciphise ukusebenza kwebhethri nempilo.

Injongo eyinhloko yokuphathwa kwe-thermal ukwenza iphakethe lebhethri lihlale lisebenza ngaphakathi kwebanga lokushisa elifanele ukuze kugcinwe isimo esingcono kakhulu sokusebenza sephakethe lebhethri. Uhlelo lokuphatha ukushisa kwebhethri ngokuyinhloko luhlanganisa imisebenzi emithathu: ukuchithwa kokushisa, ukushisa kwangaphambili kanye nokulinganisa izinga lokushisa. Ukukhipha ukushisa nokushisa kuqala kulungiswa ngokuyinhloko ngomthelela ongaba khona wezinga lokushisa lendawo yangaphandle kubhethri. Ukulinganisa izinga lokushisa kusetshenziselwa ukunciphisa umehluko wezinga lokushisa ngaphakathi kwephakethe lebhethri futhi kuvimbele ukubola okusheshayo okubangelwa ukushisa ngokweqile kwengxenye ethile yebhethri.

Amasistimu okulawula ukushisa kwebhethri asetshenziswa ezimotweni zikagesi manje ezisemakethe ahlukaniswe ikakhulukazi izigaba ezimbili: okomoya opholile kanye ne-liquid-cooled.

Umgomo weisistimu yokulawula ukushisa okupholile emoyeni kufana kakhulu nomgomo wekhompyutha wokuqeda ukushisa, isiphephetha-moya esipholile sifakwa engxenyeni eyodwa yephakethe lebhethri, kanti enye iphethelo inesikhala, esisheshisa ukugeleza komoya phakathi kwamabhethri ngomsebenzi wefeni, ukuze kususwe ukushisa okukhishwa ibhethri lapho isebenza.

Ukukubeka ngembaba, ukupholisa komoya kuwukwengeza isiphephetha-moya eceleni kwephakethe lebhethri, bese upholisa iphakethe lebhethri ngokufutha isiphephetha-moya, kodwa umoya ovunguza ifeni uzophazanyiswa izici zangaphandle, futhi ukusebenza kahle kokupholisa komoya kuzoncipha lapho izinga lokushisa langaphandle liphezulu. Njengoba nje ukufutha isiphephetha-moya akukwenzi upholile ngosuku olushisayo. Inzuzo yokupholisa umoya yisakhiwo esilula kanye nezindleko eziphansi.

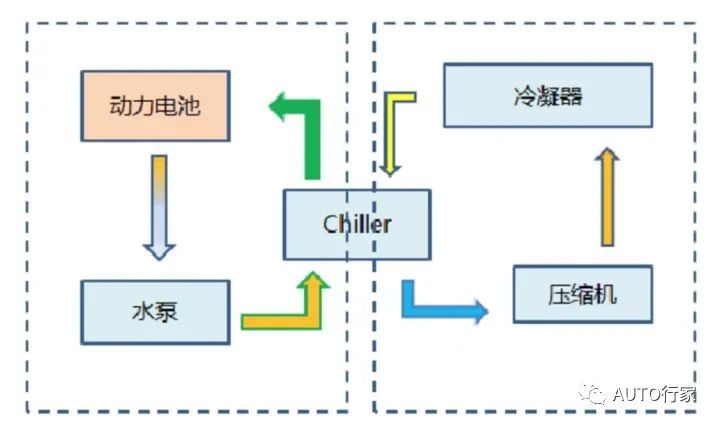

Ukupholisa okuwuketshezi kususa ukushisa okukhiqizwa ibhethri phakathi nomsebenzi ngesipholisi esisepayipini lokupholisa ngaphakathi kwephakethe lebhethri ukuze kuzuzwe umphumela wokunciphisa izinga lokushisa lebhethri. Kusukela kumthelela wokusetshenziswa wangempela, i-liquid medium ine-coefficient yokudlulisa ukushisa okuphezulu, umthamo omkhulu wokushisa, nesivinini sokupholisa esisheshayo, futhi i-Xiaopeng G3 isebenzisa isistimu yokupholisa ewuketshezi enezinga eliphezulu lokupholisa kahle.

Ngamagama alula, umgomo wokupholisa uketshezi ukuhlela ipayipi lamanzi ephaketheni lebhethri. Uma izinga lokushisa lephakethe lebhethri liphezulu kakhulu, amanzi abandayo athululelwa epayipini lamanzi, futhi ukushisa kuthathwa ngamanzi abandayo ukuze kuphole. Uma izinga lokushisa lephakethe lebhethri liphansi kakhulu, lidinga ukushisisa.

Uma imoto ishayelwa ngamandla noma ishajwa ngokushesha, inani elikhulu lokushisa liyakhiqizwa ngesikhathi sokushajwa nokushajwa kwebhethri. Uma izinga lokushisa lebhethri liphezulu kakhulu, vula isicindezela, bese isiqandisi esinezinga lokushisa eliphansi sigeleza esipholisayo epayipini lokupholisa lesishintshi sebhethri. Isipholile esinezinga lokushisa eliphansi sigelezela kuphakethe lebhethri ukuze sisuse ukushisa, ukuze ibhethri ikwazi ukugcina izinga lokushisa elingcono kakhulu, okuthuthukisa kakhulu ukuphepha nokuthembeka kwebhethri phakathi nokusetshenziswa kwemoto futhi kufinyeze isikhathi sokushaja.

Ebusika obubanda kakhulu, ngenxa yezinga lokushisa eliphansi, umsebenzi wamabhethri e-lithium uyancishiswa, ukusebenza kwebhethri kuncipha kakhulu, futhi ibhethri alikwazi ukukhishwa kwamandla aphezulu noma ukushaja okusheshayo. Ngalesi sikhathi, vula isifudumezili samanzi ukushisisa isipholile kwisekhethi yebhethri, futhi isipholile sezinga eliphezulu lokushisa sishisisa ibhethri. Iqinisekisa ukuthi imoto ingaba nekhono lokushaja ngokushesha kanye nebanga lokushayela elide endaweni enezinga eliphansi lokushisa.

Isilawuli se-elekthronikhi sedrayivu kagesi kanye nezingxenye zikagesi ezinamandla amakhulu ezipholisa ukuchithwa kokushisa

Izimoto ezintsha zamandla zizuze imisebenzi ebanzi yokufakwa kukagesi, futhi uhlelo lwamandla kaphethiloli lushintshiwe lwaba uhlelo lwamandla kagesi. Ibhethri lamandla liphuma phezuluI-voltage engu-370V DC ukuhlinzeka ngamandla, ukupholisa nokufudumeza imoto, nokuhlinzeka ngamandla ezingxenyeni ezihlukahlukene zikagesi emotweni. Ngesikhathi sokushayela imoto, izingxenye zikagesi ezinamandla amakhulu (njengamamotho, i-DCDC, izilawuli zezimoto, njll.) zizokhipha ukushisa okukhulu. Izinga lokushisa eliphezulu lezinto ezisebenza ngogesi lingase libangele ukwehluleka kwemoto, ukuncipha kwamandla ngisho nezingozi zokuphepha. Ukulawulwa kokushiswa kwemoto kudinga ukuqeda ukushisa okukhiqizwa kusenesikhathi ukuze kuqinisekiswe ukuthi izingxenye zikagesi ezinamandla kakhulu zemoto zisebangeni lokushisa eliphephile lokusebenza.

Isistimu yokulawula i-elekthronikhi ye-G3 yedrayivu kagesi yamukela ukuchithwa kokushisa okupholisa uketshezi ekulawuleni okushisayo. Isipholile esisephayiphini lesistimu yephampu ye-elekthronikhi sigeleza enjini nakwezinye izinto zokushisisa ukuze sithwale ukushisa kwezingxenye zikagesi, bese sigeleza kurediyetha endaweni yokushisa engaphambili yemoto, futhi ifeni ye-elekthronikhi iyavulwa ukuze ipholise isipholile esinezinga eliphezulu lokushisa.

Eminye imicabango mayelana nentuthuko yesikhathi esizayo yemboni yokuphatha okushisayo

Ukusetshenziswa kwamandla okuphansi:

Ukuze kuncishiswe ukusetshenziswa kwamandla okukhulu okubangelwa isimo somoya, umoya wepompo lokushisa uthole ukunakwa okuphezulu kancane kancane. Nakuba isistimu yephampu yokushisa evamile (esebenzisa u-R134a njengesiqandisi) inemikhawulo ethile endaweni esetshenziswayo, njengezinga lokushisa eliphansi kakhulu (ngezansi -10° C) ayikwazi ukusebenza, isiqandisi endaweni yokushisa ephezulu akufani ne-air conditioning yemoto kagesi evamile. Kodwa-ke, ezingxenyeni eziningi zaseShayina, inkathi yentwasahlobo nekwindla (izinga lokushisa elizungezile) linganciphisa ngempumelelo ukusetshenziswa kwamandla kwesimo somoya, futhi isilinganiso sokusebenza kahle kwamandla siphindwe izikhathi ezingu-2 kuya kwezingu-3 kunezifudumezi zikagesi.

Umsindo ophansi:

Ngemuva kokuthi imoto kagesi ingenawo umthombo womsindo wenjini, umsindo owenziwe ukusebenza kwei-compressorkanye nefeni ye-elekthronikhi engaphambili uma isiqandisi sivulwa ukuze sifakwe esiqandisini kulula ukukhononda ngabasebenzisi. Imikhiqizo yabalandeli be-elekthronikhi esebenza kahle nethule kanye nama-compressor amakhulu okuthutha asiza ukwehlisa umsindo obangelwa ukusebenza ngenkathi kukhulisa amandla okupholisa.

Izindleko eziphansi:

Izindlela zokupholisa nezokushisa zesistimu yokuphatha okushisayo ngokuvamile zisebenzisa isistimu yokupholisa uketshezi, futhi isidingo sokushisa sokushisisa kwebhethri nokushisisa komoya endaweni yokushisa ephansi sikhulu kakhulu. Isixazululo samanje ukukhulisa i-heater kagesi ukwandisa ukukhiqizwa kokushisa, okuletha izindleko zezingxenye eziphezulu kanye nokusetshenziswa kwamandla aphezulu. Uma kukhona impumelelo kubuchwepheshe bebhethri ukuze kuxazululwe noma kuncishiswe izimfuneko zezinga lokushisa eliqinile lamabhethri, kuzoletha ukuthuthukiswa okuhle ekwakhiweni nasezindlekweni zamasistimu okuphatha okushisayo. Ukusetshenziswa kahle kokushisa kwemfucuza okukhiqizwa yinjini ngesikhathi sokusebenza kwemoto nakho kuzosiza ekunciphiseni ukusetshenziswa kwamandla kwesistimu yokulawula ukushisa. Okuhunyushwe emuva ukuncishiswa komthamo webhethri, ukuthuthukiswa kwebanga lokushayela, nokwehliswa kwezindleko zemoto.

Uhlakaniphile:

Izinga eliphezulu lokufakwa kukagesi yindlela yokuthuthukiswa kwezimoto zikagesi, futhi ama-air conditioner endabuko anqunyelwe kuphela emisebenzini yesiqandisi nokushisisa ukuthuthukisa ubuhlakani. I-air conditioning ingathuthukiswa nakakhulu ekusekelweni kwedatha enkulu ngokusekelwe emikhubeni yemoto yomsebenzisi, njengemoto yomndeni, izinga lokushisa le-air conditioning lingashintshwa ngobuhlakani kubantu abahlukene ngemva kokungena emotweni. Vula i-air conditioning ngaphambi kokuphuma ukuze izinga lokushisa emotweni lifinyelele izinga lokushisa elikhululekile. I-air outlet kagesi ehlakaniphile ingakwazi ukulungisa ngokuzenzakalelayo isiqondiso se-outlet ngokuya ngenani labantu emotweni, indawo kanye nobukhulu bomzimba.

Isikhathi sokuthumela: Oct-20-2023